Choosing the Right Industrial Heat Pump: Air Source vs. Water Source vs. Dual Source

Published on May 4, 2025

Selecting the optimal heat pump system is crucial for maximizing efficiency and return on investment in industrial and commercial settings. The primary heat source – air, water, or a combination – significantly impacts performance, installation complexity, and operational costs. Let's delve into the specifics of Air Source, Water Source, and Dual Source heat pumps to help you make an informed decision.

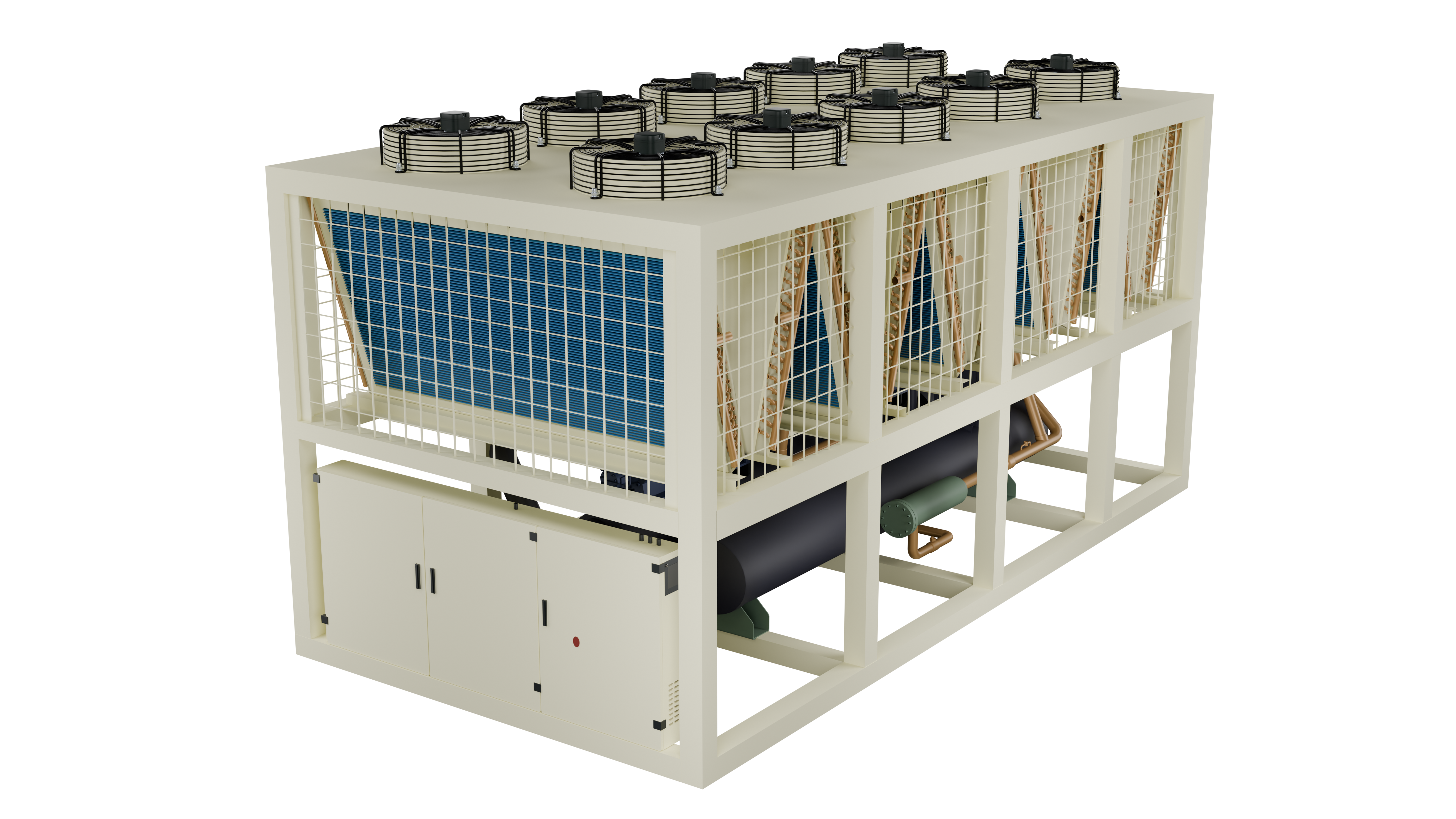

Air Source Heat Pumps (ASHPs)

ASHPs extract thermal energy directly from the ambient air. They are often the most straightforward to install, requiring only an outdoor unit connected to your internal heating system.

Pros for Industrial/Commercial Use:

- Lower Balance of Plant: Generally less expensive balance of plant costs due to simpler installation without groundwork or water access requirements.

- Installation Flexibility: Can be installed in various locations where sufficient airflow is available, suitable for retrofitting existing facilities.

- Reduced Complexity: Fewer components compared to water-source systems, potentially leading to simpler maintenance routines.

Cons to Consider:

- Variable Efficiency: Performance (Coefficient of Performance - COP) fluctuates with ambient air temperature. Efficiency decreases significantly in very cold conditions, potentially requiring supplemental heating.

- Defrost Cycles: In colder climates, ASHPs require defrost cycles, consuming energy and temporarily reducing heating output.

Water Source Heat Pumps (WSHPs)

WSHPs utilize a stable water source – such as groundwater, surface water (lakes, rivers), or industrial process water (like cooling tower effluent) – as the heat exchange medium. This often leads to higher and more consistent efficiency.

Pros for Industrial/Commercial Use:

- Higher & Stable Efficiency: Water temperatures are generally more stable than air temperatures year-round, leading to consistently higher COPs and lower operating costs.

- Waste Heat Recovery Potential: Ideal for leveraging waste heat from industrial processes or cooling systems, turning thermal discharge into a valuable asset.

- No Defrost Cycles: Eliminates energy loss associated with defrosting.

Cons to Consider:

- Higher Balancce of Plant Costs: Requires access to a suitable water source, potentially involving drilling (for groundwater), piping, or integration with existing water systems.

- Water Quality & Management: Water source quality needs assessment and potential treatment. Regulations regarding water usage and discharge may apply.

- Site Dependency: Feasibility is heavily dependent on the availability and accessibility of a reliable water source.

Dual Source Heat Pumps (DSHPs)

Dual Source systems offer the best of both worlds. These advanced heat pumps can intelligently switch between or simultaneously utilize both air and water as heat sources. Typically, they prioritize the water source when available (e.g., process waste heat) due to its higher efficiency. When the water source is insufficient or unavailable, the system seamlessly supplements or switches entirely to the air source to meet the heating demand.

Pros for Industrial/Commercial Use:

- Optimized Efficiency: Maximizes operational efficiency by preferentially using the most effective heat source available at any given time.

- Enhanced Reliability: Provides heating continuity even if one source becomes temporarily limited (e.g., low process water flow, extreme cold air).

- Maximum Resource Utilization: Particularly effective in facilities with variable waste heat streams, ensuring consistent output by supplementing with air when needed.

- Adaptability: Offers flexibility in complex industrial environments with fluctuating operational parameters.

Cons to Consider:

- Highest Complexity & Cost: Integrates components from both air and water source systems, leading to higher initial investment and potentially more complex control systems and maintenance.

- Integration Planning: Requires careful design and integration to manage the switching and/or blending between the two sources effectively.

Making the Right Choice

The ideal heat pump depends on your specific operational needs, site conditions, budget, and long-term energy strategy:

- Choose Air Source if upfront cost and installation simplicity are primary drivers, and ambient temperatures are generally moderate.

- Opt for Water Source if a reliable water source (especially waste heat) is readily available and maximizing long-term efficiency and operational savings is the goal.

- Consider Dual Source for complex applications demanding the highest reliability and optimized efficiency across varying conditions, especially where variable waste heat streams can be leveraged.

Need Expert Guidance?

Evaluating heat sources, calculating potential ROI, and designing the optimal system requires expertise. Let Titan Heat Pump help you navigate these choices.

Discuss Your Project With Us